Vintage Sewing Machine Shop.....Come on in and sit a spell

Super Member

Join Date: Feb 2012

Posts: 8,091

Will get back to you tomorrow on this.

Joe

Super Member

Join Date: Feb 2012

Posts: 8,091

Super Member

Join Date: Feb 2012

Posts: 8,091

I need a donor machine, but I'm so soft hearted, I'd probably try to fix it instead. (My furgirls are rescues, too). The Admiral needs a light and a foot pedal and the Universal may need a foot pedal.

The Universal has another problem. It's a turquoise Japanese made ZZ machine. It ZZs well, but it won't straight stitch. Anyone have any idea on what the magic setting is? I have no manual and didn't think I'd need one, but this has me stumped. Nanamoms is going to share a manual with me when she gets it, but it's in a different location now. Luckily, I don't need it to SS _ I have plenty of machines that do. The Universal does have the buttonhole stitch that I want. It needs a tiny tension adjustment but I can do that. Just haven't had my small tools and the machine in the same room. Why won't it straight stitch?

The Universal has another problem. It's a turquoise Japanese made ZZ machine. It ZZs well, but it won't straight stitch. Anyone have any idea on what the magic setting is? I have no manual and didn't think I'd need one, but this has me stumped. Nanamoms is going to share a manual with me when she gets it, but it's in a different location now. Luckily, I don't need it to SS _ I have plenty of machines that do. The Universal does have the buttonhole stitch that I want. It needs a tiny tension adjustment but I can do that. Just haven't had my small tools and the machine in the same room. Why won't it straight stitch?

I wouldn't part one out just for that. Lights can also be had. Just look a bit and you'll see.

Joe

Super Member

Join Date: Feb 2012

Posts: 8,091

[QUOTE=Mizkaki;5040835]Joe,

The feed dog cam is way off/ out of time. This cam is what is being hit by the stitch length slide.

Feed dog timing should be adjusted so that the top of the feed dog teeth are level with the needle plate when the eye of the needle descends into the hole of the plate. The feed timing adjustment on your machine is a cam on the main upper shaft.

To adjust the feed timing set the needle eye so that it is just going into the needle plate hole. Then loosen the set screw slightly and turn the cam to have the top of the teeth just go below the level of the plate. Tighten the screw and test.Note that when you advance or retard the feed timing you will also increase or reduce the maximum stitch length. The picture below is of a different machine, but very similar and I have marked with a yellow arrow the set screw that you need to loosen. Set the stitch length during this adjustment at midway so as to get the slide out of the way of the cam.

[ATTACH=CONFIG]318141[/ATTACH]

He has several problems. First was the feed dogs hit the front side of the needle plate. I adjusted that so it doesn't happen, but either I caused another problem, or it was there but I didn't know it. I suspect it was there as when he was put in reverse he banged and clunked horribly. Now he only does that if I hold the stitch lever down.

When the stitch lever is lowered all the way to the bottom for maximum length stitches, the feed regulator (T2, Figs 30 and 32 ) in the 15-91 service manual is in the way of the cam next to it.

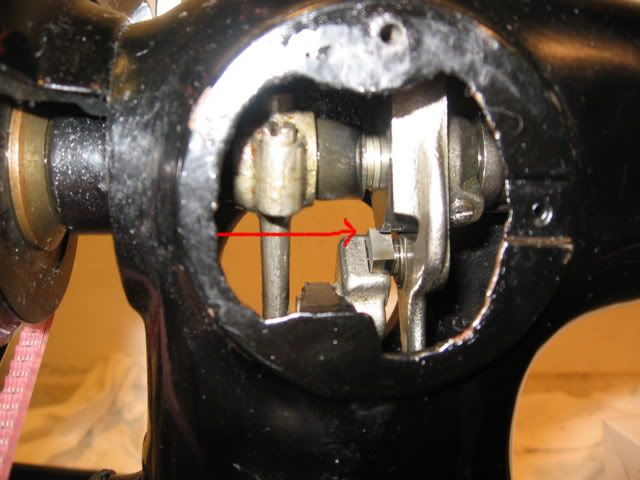

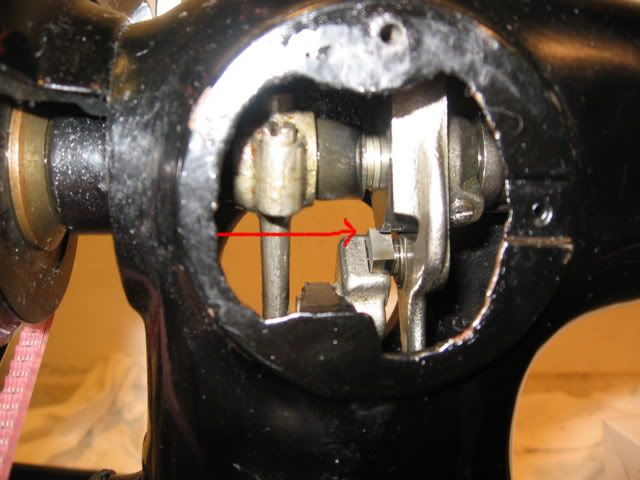

The arrow points to the interference point in the following pictures:

Cathy,

Cathy,

Thanks for the diagnosis and what to adjust.

When I worked on this before I tried to move that cam. I couldn't get it to budge. Is this the only screw for that cam? If I remember right (questionable at 12:15AM) there are two screws. When I had them broke loose the last time I didn't know what to use as a reference point. Thanks, I do now. What is the best way to turn that cam? Will try this tomorrow and get back with you.

Joe

The feed dog cam is way off/ out of time. This cam is what is being hit by the stitch length slide.

Feed dog timing should be adjusted so that the top of the feed dog teeth are level with the needle plate when the eye of the needle descends into the hole of the plate. The feed timing adjustment on your machine is a cam on the main upper shaft.

To adjust the feed timing set the needle eye so that it is just going into the needle plate hole. Then loosen the set screw slightly and turn the cam to have the top of the teeth just go below the level of the plate. Tighten the screw and test.Note that when you advance or retard the feed timing you will also increase or reduce the maximum stitch length. The picture below is of a different machine, but very similar and I have marked with a yellow arrow the set screw that you need to loosen. Set the stitch length during this adjustment at midway so as to get the slide out of the way of the cam.

[ATTACH=CONFIG]318141[/ATTACH]

He has several problems. First was the feed dogs hit the front side of the needle plate. I adjusted that so it doesn't happen, but either I caused another problem, or it was there but I didn't know it. I suspect it was there as when he was put in reverse he banged and clunked horribly. Now he only does that if I hold the stitch lever down.

When the stitch lever is lowered all the way to the bottom for maximum length stitches, the feed regulator (T2, Figs 30 and 32 ) in the 15-91 service manual is in the way of the cam next to it.

The arrow points to the interference point in the following pictures:

Thanks for the diagnosis and what to adjust.

When I worked on this before I tried to move that cam. I couldn't get it to budge. Is this the only screw for that cam? If I remember right (questionable at 12:15AM) there are two screws. When I had them broke loose the last time I didn't know what to use as a reference point. Thanks, I do now. What is the best way to turn that cam? Will try this tomorrow and get back with you.

Joe

Super Member

Join Date: Feb 2012

Posts: 8,091

Here is a link to a parts manual with pictures of the 99K:

http://www.parts.singerco.com/IPpart...9K26_27_28.pdf

Go to page 7 plate 2394.

The oscillating hook part #32520 is the big round thing

Towards the bottom of the page, part # 32594 is the part that attaches the bottom of the hook to the levers that make it work.

Page 4 plate 895.

The feed dog is the toothy thing, part #32600. It's screw is on plate #2400 and it's part #191C

The part above it, #33635, and the two parts to the right of it, #'s 32529 and 33613 are part of the thread take-up lever assembly.

I haven't found where the screws for that are located.

So to review, I need the oscillating hook, the feed dog and screw, and the thread take up lever assembly.

Note one of the screws on the thread take up assembly has left handed threads. It's the one with the concave slot. Easy to see.

If this doesn't help, PM me your email addy and I'll take some genuine digital images and send them to you.

Joe

Super Member

Join Date: Apr 2007

Location: North Carolina - But otherwise, NOTW

Posts: 7,940

And this is why I want a basement. The legs on this lady are cute! http://sfbay.craigslist.org/eby/atq/2888084166.html

[ATTACH=CONFIG]318019[/ATTACH]

[ATTACH=CONFIG]318019[/ATTACH]

Super Member

Join Date: Apr 2007

Location: North Carolina - But otherwise, NOTW

Posts: 7,940

Cathy I'll start saving up my nickels and dimes for gas to come up. Just give me a target date! :-) Can't wait to see everyone again.

Super Member

Join Date: Apr 2007

Location: North Carolina - But otherwise, NOTW

Posts: 7,940

I will do my best!

Got some time to plan a date...I'm going to be paying off some plastic for a bit...the spousal unit's daughters are coming to visit for his birthday at my expense...it'll be the first time he's seen them in 13 years, and he doesn't know they're coming. I put it together with them, and they're excited to be able to surprise him! Hopefully this visit will heal some old wounds, on both sides.

Got some time to plan a date...I'm going to be paying off some plastic for a bit...the spousal unit's daughters are coming to visit for his birthday at my expense...it'll be the first time he's seen them in 13 years, and he doesn't know they're coming. I put it together with them, and they're excited to be able to surprise him! Hopefully this visit will heal some old wounds, on both sides.

You're a good woman, Charlee....no matter what anyone says!

Seriously...that's a very kind thing to do for your DH. I know how it feels to be the step parent...sometimes not so easy. Hope everything goes as planned.

Seriously...that's a very kind thing to do for your DH. I know how it feels to be the step parent...sometimes not so easy. Hope everything goes as planned.

Super Member

Join Date: Feb 2012

Posts: 8,091

vintagemotif,

Just make sure when you get the basement you get:

( In order of importance)

1 - A dry basement, check carefully for mold, mildew, or previous flooding.

2 - Ample head room for the tallest person in your family. I about killed myself in the basement in the first house we lived in here in Springfield. Those floor beams are solid.

2a - Wide tall stairs down to the basement. Having to bend over to avoid a concussion or bend and twist to get down the stairs is a pain in the a ..... 'em butt.

3 - Ample windows that open for ventilation.

4 - Light, you need lots of light. That can be worked on though.

Hope you get pretty legs a good place to set up.

Joe

Just make sure when you get the basement you get:

( In order of importance)

1 - A dry basement, check carefully for mold, mildew, or previous flooding.

2 - Ample head room for the tallest person in your family. I about killed myself in the basement in the first house we lived in here in Springfield. Those floor beams are solid.

2a - Wide tall stairs down to the basement. Having to bend over to avoid a concussion or bend and twist to get down the stairs is a pain in the a ..... 'em butt.

3 - Ample windows that open for ventilation.

4 - Light, you need lots of light. That can be worked on though.

Hope you get pretty legs a good place to set up.

Joe

Super Member

Join Date: Apr 2007

Location: North Carolina - But otherwise, NOTW

Posts: 7,940

This man was very clever and frugal in repairing this treadle.He also has a very nice Bernina.http://www.youtube.com/watch?v=dxUj6...eature=related

Thread

Thread Starter

Forum

Replies

Last Post

Stitchnripper

Main

5

10-17-2018 09:01 AM

AngieS

Main

38

10-06-2011 10:06 PM

craftybear

Offline Events, Announcements, Discussions

34

09-09-2011 12:36 PM