Kenmore Electric Rotary Sewing Machine or 120-49 is here.

#1

Super Member

Thread Starter

Join Date: Feb 2012

Posts: 8,091

The UPS guy brought my new toy today just after lunch time. No damage from shipping. All the accessories were there as well as the owners manual.

The original text said the motor ran, the light worked but the needle did not go up and down. They were right, the top shaft was jammed up solid.

I've been told these machines jam up due to the nylon bearings used in them. Well, this machine has bronze bushings on the main shaft, the presser bar shaft and needle rod. Also the underneath shafts are mounted in bronze bushings also. The only nylon parts I've found so far are an idler bushing that puts the tension on the drive chain, yep the main shaft drives the bottom shafts with a steel chain. There is an tubular angled piece that controls the stitch length that's nylon, and a nylon cam in the feed dog areas.

There is also a part in the thread take up lever assembly that's plastic. There may be more, but I found none in critical high load areas.

If the condition of this machine is any indication of it's life, it was used a lot. No closet queen this one. It was full of what looked like wool lint. Lots and lots of it. The feed dogs were totally covered in it. This is a well used machine.

So, I started putting the Tri-Flo oil to it. If it moved, turned, slid, rotated, or even looked like it would do any of the above it got oiled. And oiled, and oiled.

I pulled the hand wheel clutch nob off and there was a big slot in the end of the shaft. So using a screw driver I began to put the pressure on it trying to get it to turn. It took a bit of coaxing but it turned. So, with the top two bronze bushings floating in oil I've been turning and turning till I had to take a break. While I'm typing this I stood the machine on it's end and poured more Tri-Flo on the bushings. Some really icky brown stuff is coming out of the bushings so I'm figuring that poor machine has been use for many years then retired without a single lube job in it's life.

The motor is even covered in the brown wool lint. It's a Delco motor by the way ... with oil holes.

I found many places to lube this machine. It's not really meant to be left to go dry.

I'm pretty sure she'll sew again.

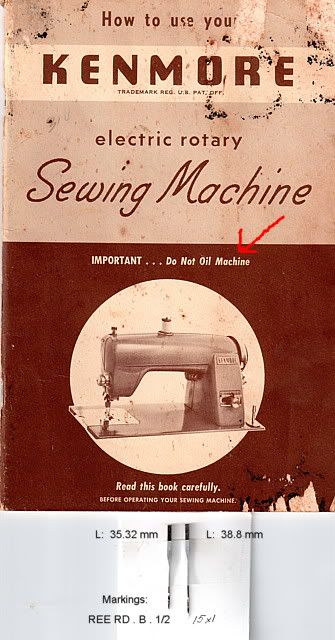

My only worry is needles. The needle I took out of the machine is a full 3/16" shorter than a standard 15x1.

The markings on it are: REE RD . B. 1/2 . The flat shank is longer than a 15x1s but the needle is shorter and it has a real stumpy point with the eye very close to the end.

The owners manual says use a "Kenmore 49" needle and shows a larger than life pic of it. But it gives no other information.

I'm going to try ISMACS to see if I can find a listing for the "Kenmore 49" needle, but I won't hold my breath.

Anybody have any idea on this?

More reports will be coming along with pics.

Joe

The original text said the motor ran, the light worked but the needle did not go up and down. They were right, the top shaft was jammed up solid.

I've been told these machines jam up due to the nylon bearings used in them. Well, this machine has bronze bushings on the main shaft, the presser bar shaft and needle rod. Also the underneath shafts are mounted in bronze bushings also. The only nylon parts I've found so far are an idler bushing that puts the tension on the drive chain, yep the main shaft drives the bottom shafts with a steel chain. There is an tubular angled piece that controls the stitch length that's nylon, and a nylon cam in the feed dog areas.

There is also a part in the thread take up lever assembly that's plastic. There may be more, but I found none in critical high load areas.

If the condition of this machine is any indication of it's life, it was used a lot. No closet queen this one. It was full of what looked like wool lint. Lots and lots of it. The feed dogs were totally covered in it. This is a well used machine.

So, I started putting the Tri-Flo oil to it. If it moved, turned, slid, rotated, or even looked like it would do any of the above it got oiled. And oiled, and oiled.

I pulled the hand wheel clutch nob off and there was a big slot in the end of the shaft. So using a screw driver I began to put the pressure on it trying to get it to turn. It took a bit of coaxing but it turned. So, with the top two bronze bushings floating in oil I've been turning and turning till I had to take a break. While I'm typing this I stood the machine on it's end and poured more Tri-Flo on the bushings. Some really icky brown stuff is coming out of the bushings so I'm figuring that poor machine has been use for many years then retired without a single lube job in it's life.

The motor is even covered in the brown wool lint. It's a Delco motor by the way ... with oil holes.

I found many places to lube this machine. It's not really meant to be left to go dry.

I'm pretty sure she'll sew again.

My only worry is needles. The needle I took out of the machine is a full 3/16" shorter than a standard 15x1.

The markings on it are: REE RD . B. 1/2 . The flat shank is longer than a 15x1s but the needle is shorter and it has a real stumpy point with the eye very close to the end.

The owners manual says use a "Kenmore 49" needle and shows a larger than life pic of it. But it gives no other information.

I'm going to try ISMACS to see if I can find a listing for the "Kenmore 49" needle, but I won't hold my breath.

Anybody have any idea on this?

More reports will be coming along with pics.

Joe

Last edited by J Miller; 05-25-2012 at 10:53 AM.

#2

Super Member

Thread Starter

Join Date: Feb 2012

Posts: 8,091

OK, here we go .... Pics of my new to me Kenmore 120-491.

This is what GW said I'd get, and I did:

When I got it home I checked it thoroughly. As they said it was locked up. Filthy inside from brown wool type lint.

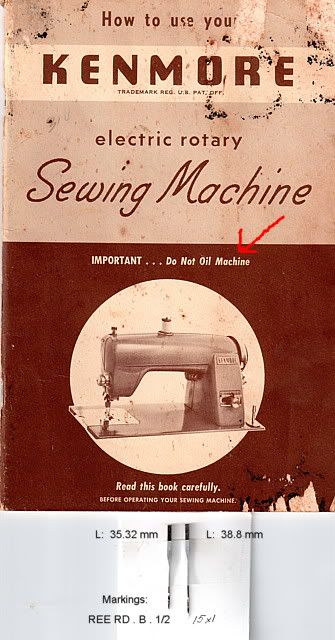

But nothing was missing or broken. That always helps. And I'm glad I didn't look closely at the manual cover till after I had it running. One thing is for positive sure, this was not a closet queen. This is a well used but not abused machine.

Here is it with the outer shell removed. Looks really hokey to me but it gets the job done I guess.

In this view you can get an idea of how filthy it was. Just look at the feed dog area. You can also see the right main shaft bronze bushing near the hand wheel, and the pressure foot and needle shaft bronze bushings too.

Here is the motor. It's a Delco, made by GM, 1.5 Amp motor. It is oil-able and was dry, dry, dry and covered with the brown wool lint.

It is spring loaded and once the oil got to the bushings it lacks nothing in giddyap and go.

Here's a couple from straight on, front then back:

While I had it apart I pumped the oil in it and worked it and worked it and worked it until I finally got some movement. I had to use a screw driver in the slot at the end of the main shaft under the clutch to get it to move.

I worked it for over an hour by hand then took a break. After my break an idea hit me. Use my drill motor to drive the shaft while I put more oil in the bushings. So I chucked a bit in the drill and did just that. It worked.

After that I cranked the clutch down and kept turning it until the motor could drive it. Then with the foot controller pedal to the floor I poured more oil in the bushings as the motor did the work. Gradually the speed picked up until it was running pretty good. By the time I was finished it would even start with out my help.

We had a snack and after that I put the shell back on and put all the peripherals back on. Put the needle and bobbin in and threaded it up. Because the needle is slightly bent I turned it by hand to see if it would actually sew. It did. So I put the foot controller on the floor and tried it out. I was pleased to see it sews. Not only does it sew, it makes some really nice stitches too. Here's a pic of the machine with the test stitch felt and all the accessories I got with it:

After I was finished I was putting the pics through my photo program to reduce them for the forum when I saw the caution on the cover of the owners manual:

"IMPORTANT ... Do Not Oil Machine". Really now. Well, one thing is for sure, had I not oiled it, it would have never sewed again. It was jammed up and jelly tight. Now it turns freely. I suspect there was lube already in the bronze bushings that lasted a period of time. After that the idea was to convince the owner to buy a new machine. That's just my theory now, nothing I know for sure.

The needle is shorter than a 15x1, see the bottom of the pic above. I'm going to do some more research but it is the correct needle. I'll make a trip to my LSMG tomorrow and hope he's got some.

Does anyone have any idea of what the correct number for this needle might be?

Well, she's kinda ugly and I think I'll name her something appropriate as soon as I can think of something.

Joe

This is what GW said I'd get, and I did:

When I got it home I checked it thoroughly. As they said it was locked up. Filthy inside from brown wool type lint.

But nothing was missing or broken. That always helps. And I'm glad I didn't look closely at the manual cover till after I had it running. One thing is for positive sure, this was not a closet queen. This is a well used but not abused machine.

Here is it with the outer shell removed. Looks really hokey to me but it gets the job done I guess.

In this view you can get an idea of how filthy it was. Just look at the feed dog area. You can also see the right main shaft bronze bushing near the hand wheel, and the pressure foot and needle shaft bronze bushings too.

Here is the motor. It's a Delco, made by GM, 1.5 Amp motor. It is oil-able and was dry, dry, dry and covered with the brown wool lint.

It is spring loaded and once the oil got to the bushings it lacks nothing in giddyap and go.

Here's a couple from straight on, front then back:

While I had it apart I pumped the oil in it and worked it and worked it and worked it until I finally got some movement. I had to use a screw driver in the slot at the end of the main shaft under the clutch to get it to move.

I worked it for over an hour by hand then took a break. After my break an idea hit me. Use my drill motor to drive the shaft while I put more oil in the bushings. So I chucked a bit in the drill and did just that. It worked.

After that I cranked the clutch down and kept turning it until the motor could drive it. Then with the foot controller pedal to the floor I poured more oil in the bushings as the motor did the work. Gradually the speed picked up until it was running pretty good. By the time I was finished it would even start with out my help.

We had a snack and after that I put the shell back on and put all the peripherals back on. Put the needle and bobbin in and threaded it up. Because the needle is slightly bent I turned it by hand to see if it would actually sew. It did. So I put the foot controller on the floor and tried it out. I was pleased to see it sews. Not only does it sew, it makes some really nice stitches too. Here's a pic of the machine with the test stitch felt and all the accessories I got with it:

After I was finished I was putting the pics through my photo program to reduce them for the forum when I saw the caution on the cover of the owners manual:

"IMPORTANT ... Do Not Oil Machine". Really now. Well, one thing is for sure, had I not oiled it, it would have never sewed again. It was jammed up and jelly tight. Now it turns freely. I suspect there was lube already in the bronze bushings that lasted a period of time. After that the idea was to convince the owner to buy a new machine. That's just my theory now, nothing I know for sure.

The needle is shorter than a 15x1, see the bottom of the pic above. I'm going to do some more research but it is the correct needle. I'll make a trip to my LSMG tomorrow and hope he's got some.

Does anyone have any idea of what the correct number for this needle might be?

Well, she's kinda ugly and I think I'll name her something appropriate as soon as I can think of something.

Joe

#5

Super Member

Thread Starter

Join Date: Feb 2012

Posts: 8,091

In the pic below look at the little dot inside the red circle. That is an oil hole. There is one on both ends.

The motors with these holes can be oiled, if there is no holes they are usually can't be oiled..

Joe

#6

Super Member

Join Date: Aug 2011

Location: Millville, NJ

Posts: 1,835

Joe,

Pretty neat how the "hood" comes completely off and power shouldn't be lacking with that motor. If needles are difficult to come by, I'd be curious if a 15x1 with a few mm ground off the top would work. I was reading somewhere that your machine was made by a division of Chrysler. Nice Find

Jon

Pretty neat how the "hood" comes completely off and power shouldn't be lacking with that motor. If needles are difficult to come by, I'd be curious if a 15x1 with a few mm ground off the top would work. I was reading somewhere that your machine was made by a division of Chrysler. Nice Find

Jon

#7

Super Member

Join Date: Dec 2010

Location: Michigan

Posts: 3,334

Joe, I'm impressed at how resourceful you are.... and persistant, too. It looks like you have another great machine that was willing to sew beautiful stitches but wasn't going to get the chance unless you or some other machine enthusiast coaxed it back to life. Good Job!!

You all encourage me with your knowledge and desire to revive every vintage machine you find.

You all encourage me with your knowledge and desire to revive every vintage machine you find.

#8

Super Member

Thread Starter

Join Date: Feb 2012

Posts: 8,091

I contacted Kevin Pinkerton over at ISMACS and he suggested DCx1F needles. I'm pretty sure we have some of those here even though we've never had a machine that uses them. Now the hunt is on.

Jon,

The needle in it has a very short point. Sort of like a 206x13. I don't know if grinding the top off of a 15x1 would work. But the thought did cross my mind. The only problem is how much to grind off and how to do it consistently.

n-u-n,

I don't know what the numbers are for the stitches yet, but I ran the stitch control down to "1". Then ran some stitches. On most machines I have, when the stitches get to the 20+ per inch they loose their individual stitch.

This machine makes the most perfect itsy tinsy stitches I've seen. I'll have to do it again with a good needle and post them.

.................................................. .......................................

Next up a video of the naked Kenmore running. In color with sound.

Joe

Jon,

The needle in it has a very short point. Sort of like a 206x13. I don't know if grinding the top off of a 15x1 would work. But the thought did cross my mind. The only problem is how much to grind off and how to do it consistently.

n-u-n,

I don't know what the numbers are for the stitches yet, but I ran the stitch control down to "1". Then ran some stitches. On most machines I have, when the stitches get to the 20+ per inch they loose their individual stitch.

This machine makes the most perfect itsy tinsy stitches I've seen. I'll have to do it again with a good needle and post them.

.................................................. .......................................

Next up a video of the naked Kenmore running. In color with sound.

Joe

#10

Super Member

Join Date: Aug 2011

Location: Millville, NJ

Posts: 1,835

Thread

Thread Starter

Forum

Replies

Last Post

Fortyniner

For Vintage & Antique Machine Enthusiasts

5

04-07-2013 01:28 PM