Vintage Sewing Machine Shop.....Come on in and sit a spell

Nancy

Super Member

Join Date: Feb 2012

Posts: 8,091

Cool. Brute force. Who says you can't do the guy thing on sewing machines  . I'll check my supply of fuel hose and see if one is marked 7.9 mm. By the thickness of the hose walls I'm thinking it's fuel injection hose.

. I'll check my supply of fuel hose and see if one is marked 7.9 mm. By the thickness of the hose walls I'm thinking it's fuel injection hose.

Joe

. I'll check my supply of fuel hose and see if one is marked 7.9 mm. By the thickness of the hose walls I'm thinking it's fuel injection hose.

. I'll check my supply of fuel hose and see if one is marked 7.9 mm. By the thickness of the hose walls I'm thinking it's fuel injection hose.Joe

Nancy, my son is bringing the machine to me next week...will post a pic then. Thanks for the info.

Super Member

Join Date: Dec 2011

Location: Northern CA near Sacramento

Posts: 1,107

Joe and Grant,

I have in the past resurrected a worn out motor pulley. I moved the pulley over along it's shaft until it's edge would make contact with the handwheel. I then ran the motor at a fast clip and 'gouged' a deep groove in the old pulley's middle with a rough file. The depth of this 'gouge' was the same as the inside diameter of a bobbinwinder tire or o-ring. Slip the tire or o-ring over the pulley and realign it to the handwheel. Works perfectly. Clear as mud?????

Cathy

I have in the past resurrected a worn out motor pulley. I moved the pulley over along it's shaft until it's edge would make contact with the handwheel. I then ran the motor at a fast clip and 'gouged' a deep groove in the old pulley's middle with a rough file. The depth of this 'gouge' was the same as the inside diameter of a bobbinwinder tire or o-ring. Slip the tire or o-ring over the pulley and realign it to the handwheel. Works perfectly. Clear as mud?????

Cathy

Super Member

Join Date: Dec 2011

Location: Northern CA near Sacramento

Posts: 1,107

Lynn,

I have an 81-12. Mine was for carpet binding. The thing weighs a bloody ton! As Nancy said it takes a 81x1 needle.

Cathy

I have an 81-12. Mine was for carpet binding. The thing weighs a bloody ton! As Nancy said it takes a 81x1 needle.

Cathy

Cathy, I was thinking about pulling this thing off and put the bobbin winder post part in my drill and filing it. But I was afraid of making it more egg shaped in the process. Leaving it in a machine is much wiser because of the stable platform it has. But the flat spot on mine combined with the dry brittle and cracked condition of mine made this option, and yours, not a good one for me. If it is just a flat spot, I would seriously think about what you are suggesting as an option. I guess maybe I should have mentioned this earlier. The rubber on mine was flat spotted, really dried out, and cracked. What I did was NOT an easy thing for me to do. I like the grove idea but there is such little clearance on this particular model, I am not sure it would have worked. I love Yankee ingenuity! ~G~

Joe and Grant,

I have in the past resurrected a worn out motor pulley. I moved the pulley over along it's shaft until it's edge would make contact with the handwheel. I then ran the motor at a fast clip and 'gouged' a deep groove in the old pulley's middle with a rough file. The depth of this 'gouge' was the same as the inside diameter of a bobbinwinder tire or o-ring. Slip the tire or o-ring over the pulley and realign it to the handwheel. Works perfectly. Clear as mud?????

Cathy

I have in the past resurrected a worn out motor pulley. I moved the pulley over along it's shaft until it's edge would make contact with the handwheel. I then ran the motor at a fast clip and 'gouged' a deep groove in the old pulley's middle with a rough file. The depth of this 'gouge' was the same as the inside diameter of a bobbinwinder tire or o-ring. Slip the tire or o-ring over the pulley and realign it to the handwheel. Works perfectly. Clear as mud?????

Cathy

Super Member

Join Date: Feb 2012

Posts: 8,091

Cathy and Grant,

One of my Machines, the Minnesota B uses a drive pulley with a grove for a belt and a friction drive wheel. The end is hollow and flared over the outer wheel. The rubber drive wheel between them. I removed the rubber drive wheel then pushed the outer metal wheel in and filed off the flared part. Removed the metal wheel, put 2 3/8" grommets on the shaft then put the outer metal wheel on and tightened the set screw. Works beautifully and is easily replaced when needed. One of these days though I'll try rubber hose or perhaps bobbin winding tires.

Joe

One of my Machines, the Minnesota B uses a drive pulley with a grove for a belt and a friction drive wheel. The end is hollow and flared over the outer wheel. The rubber drive wheel between them. I removed the rubber drive wheel then pushed the outer metal wheel in and filed off the flared part. Removed the metal wheel, put 2 3/8" grommets on the shaft then put the outer metal wheel on and tightened the set screw. Works beautifully and is easily replaced when needed. One of these days though I'll try rubber hose or perhaps bobbin winding tires.

Joe

Super Member

Join Date: Dec 2011

Location: Northern CA near Sacramento

Posts: 1,107

Joe,

Picture please?

Cathy

Picture please?

Cathy

Cathy and Grant,

One of my Machines, the Minnesota B uses a drive pulley with a grove for a belt and a friction drive wheel. The end is hollow and flared over the outer wheel. The rubber drive wheel between them. I removed the rubber drive wheel then pushed the outer metal wheel in and filed off the flared part. Removed the metal wheel, put 2 3/8" grommets on the shaft then put the outer metal wheel on and tightened the set screw. Works beautifully and is easily replaced when needed. One of these days though I'll try rubber hose or perhaps bobbin winding tires.

Joe

One of my Machines, the Minnesota B uses a drive pulley with a grove for a belt and a friction drive wheel. The end is hollow and flared over the outer wheel. The rubber drive wheel between them. I removed the rubber drive wheel then pushed the outer metal wheel in and filed off the flared part. Removed the metal wheel, put 2 3/8" grommets on the shaft then put the outer metal wheel on and tightened the set screw. Works beautifully and is easily replaced when needed. One of these days though I'll try rubber hose or perhaps bobbin winding tires.

Joe

Super Member

Join Date: Dec 2011

Location: Northern CA near Sacramento

Posts: 1,107

Grant,

I've used my method on very brittle, dried out rubber. I does work even then. Probably because the old rubber is only

a place holder for the new tire, there are only light stresses on it. Probably much less stress than when it was driving the handwheel.

That said I really like your rubber hose repair.

I also really like Yankee ingenuity,

Cathy

I've used my method on very brittle, dried out rubber. I does work even then. Probably because the old rubber is only

a place holder for the new tire, there are only light stresses on it. Probably much less stress than when it was driving the handwheel.

That said I really like your rubber hose repair.

I also really like Yankee ingenuity,

Cathy

Cathy, I was thinking about pulling this thing off and put the bobbin winder post part in my drill and filing it. But I was afraid of making it more egg shaped in the process. Leaving it in a machine is much wiser because of the stable platform it has. But the flat spot on mine combined with the dry brittle and cracked condition of mine made this option, and yours, not a good one for me. If it is just a flat spot, I would seriously think about what you are suggesting as an option. I guess maybe I should have mentioned this earlier. The rubber on mine was flat spotted, really dried out, and cracked. What I did was NOT an easy thing for me to do. I like the grove idea but there is such little clearance on this particular model, I am not sure it would have worked. I love Yankee ingenuity! ~G~

Super Member

Join Date: Feb 2012

Posts: 8,091

Singer 500 is breaking it's top thread constantly.

OK, machine is a derelict that someone has messed with a bit and has some missing parts.

I have found enough parts to put it back in action:

Oiled and greased everything that moves.

Freed up the cam stack selectors.

Cleaned the hook area and the bobbin case.

Adjusted the bobbin case tension, there was none when I got it.

Adjusted the top tension, it was too tight.

Put in brand new unused needle.

The needle to hook timing is good.

The top and bobbin tension looks good when it sews.

After about an inch or two you'll hear a crunch, then a couple more stitches another crunch and the top thread breaks.

I'm not sure what's gonna become of this machine, but I want to see if I can make it sew before we make our decision.

Anybody have any ideas on what else to look for?

Joe

OK, machine is a derelict that someone has messed with a bit and has some missing parts.

I have found enough parts to put it back in action:

Oiled and greased everything that moves.

Freed up the cam stack selectors.

Cleaned the hook area and the bobbin case.

Adjusted the bobbin case tension, there was none when I got it.

Adjusted the top tension, it was too tight.

Put in brand new unused needle.

The needle to hook timing is good.

The top and bobbin tension looks good when it sews.

After about an inch or two you'll hear a crunch, then a couple more stitches another crunch and the top thread breaks.

I'm not sure what's gonna become of this machine, but I want to see if I can make it sew before we make our decision.

Anybody have any ideas on what else to look for?

Joe

Alright the problem is solved and it was none of the above. But in trying to diagnose the problems I did the following:

Took apart the top tension assembly and cleaned it. Didn't have to, it wasn't the problem, but it never hurts.

Cleaned the bobbin case and hook assembly again.

I went hunting for a couple pics someone here on the forum emailed me of how to assemble the later top tensions. I didn't find it but I found out I had a 500 manual on my thumb drive. So I checked it out and found I had missed a complete step in threading the top end. I printed the page I needed then stood in front of our 401A while I double checked my assembly of the top tension.

Went back downstairs put the tension unit in and rethreaded it correctly.

Then I tried to sew and it made it a whole 3" then crunch and broke the thread. Over and over again my wife and I (she finally got in on the act) worked with the tensions, bobbin, and cleaning trying to find out what the heck it's problem was.

Then it went crunch and just stopped. Rather than go again and break the thread I carefully removed the needle and needle plate to see where the jam up was. Well, the thread was wrapped around the bobbin case and then around the case support on the back side where the case sits. This didn't make sense at all.

It was about then that I realized the bobbin case and hook assembly and the springy thing that holds the bobbin case in was the same as the 401A. So I went upstairs again and opened up the 401A and studied it. Hmmmmmmmm.

Back downstairs to the 500. Make one adjustment and zoom zooom we're sewing. No broken threads, ZZ works, stitch patterns work, and I'm thrilled. I had to go back upstairs to get a slant shank special purpose foot to really try some patterns and when I did, the old lady made a few really nice stitches.

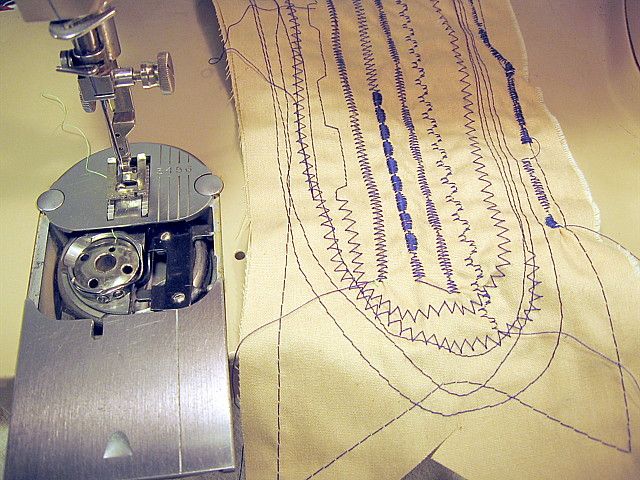

Now, I'm gonna post a pic of the bobbin area and let you all try and figure out what I had to adjust to fix the problem.

Joe

Thread

Thread Starter

Forum

Replies

Last Post

Stitchnripper

Main

5

10-17-2018 09:01 AM

AngieS

Main

38

10-06-2011 10:06 PM

craftybear

Offline Events, Announcements, Discussions

34

09-09-2011 12:36 PM