Joe,

The feed dog cam is way off/ out of time. This cam is what is being hit by the stitch length slide.

Feed dog timing should be adjusted so that the top of the feed dog teeth are level with the needle plate when the eye of the needle descends into the hole of the plate. The feed timing adjustment on your machine is a cam on the main upper shaft.

To adjust the feed timing set the needle eye so that it is just going into the needle plate hole. Then loosen the set screw slightly and turn the cam to have the top of the teeth just go below the level of the plate. Tighten the screw and test.Note that when you advance or retard the feed timing you will also increase or reduce the maximum stitch length. The picture below is of a different machine, but very similar and I have marked with a yellow arrow the set screw that you need to loosen. Set the stitch length during this adjustment at midway so as to get the slide out of the way of the cam.

[ATTACH=CONFIG]318141[/ATTACH]

[QUOTE=J Miller;5040173]

He has several problems. First was the feed dogs hit the front side of the needle plate. I adjusted that so it doesn't happen, but either I caused another problem, or it was there but I didn't know it. I suspect it was there as when he was put in reverse he banged and clunked horribly. Now he only does that if I hold the stitch lever down.

When the stitch lever is lowered all the way to the bottom for maximum length stitches, the

feed regulator (T2, Figs 30 and 32 ) in the 15-91 service manual is in the way of the cam next to it.

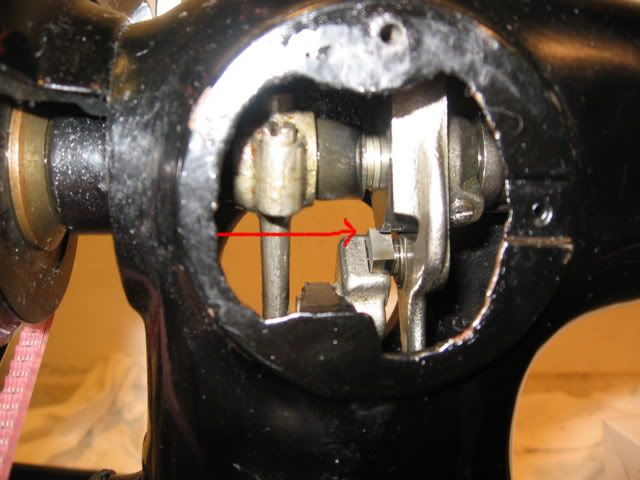

The arrow points to the interference point in the following pictures: