OK, here we go .... Pics of my new to me Kenmore 120-49

1.

This is what GW said I'd get, and I did:

When I got it home I checked it thoroughly. As they said it was locked up. Filthy inside from brown wool type lint.

But nothing was missing or broken. That always helps. And I'm glad I didn't look closely at the manual cover till after I had it running. One thing is for positive sure, this was not a closet queen. This is a well used but not abused machine.

Here is it with the outer shell removed. Looks really hokey to me but it gets the job done I guess.

In this view you can get an idea of how filthy it was. Just look at the feed dog area. You can also see the right main shaft bronze bushing near the hand wheel, and the pressure foot and needle shaft bronze bushings too.

Here is the motor. It's a Delco, made by GM, 1.5 Amp motor. It is oil-able and was dry, dry, dry and covered with the brown wool lint.

It is spring loaded and once the oil got to the bushings it lacks nothing in giddyap and go.

Here's a couple from straight on, front then back:

While I had it apart I pumped the oil in it and worked it and worked it and worked it until I finally got some movement. I had to use a screw driver in the slot at the end of the main shaft under the clutch to get it to move.

I worked it for over an hour by hand then took a break. After my break an idea hit me. Use my drill motor to drive the shaft while I put more oil in the bushings. So I chucked a bit in the drill and did just that. It worked.

After that I cranked the clutch down and kept turning it until the motor could drive it. Then with the foot controller pedal to the floor I poured more oil in the bushings as the motor did the work. Gradually the speed picked up until it was running pretty good. By the time I was finished it would even start with out my help.

We had a snack and after that I put the shell back on and put all the peripherals back on. Put the needle and bobbin in and threaded it up. Because the needle is slightly bent I turned it by hand to see if it would actually sew. It did. So I put the foot controller on the floor and tried it out. I was pleased to see it sews. Not only does it sew, it makes some really nice stitches too. Here's a pic of the machine with the test stitch felt and all the accessories I got with it:

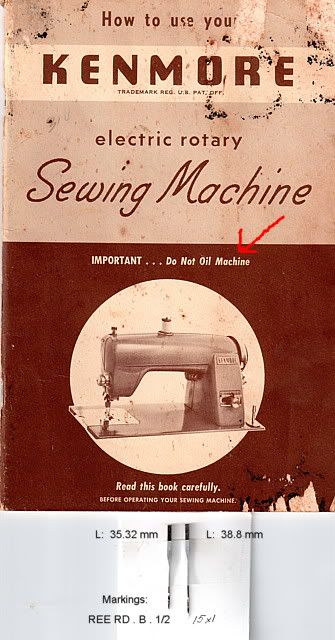

After I was finished I was putting the pics through my photo program to reduce them for the forum when I saw the caution on the cover of the owners manual:

"IMPORTANT ... Do Not Oil Machine". Really now. Well, one thing is for sure, had I not oiled it, it would have never sewed again. It was jammed up and jelly tight. Now it turns freely. I suspect there was lube already in the bronze bushings that lasted a period of time. After that the idea was to convince the owner to buy a new machine. That's just my theory now, nothing I know for sure.

The needle is shorter than a 15x1, see the bottom of the pic above. I'm going to do some more research but it is the correct needle. I'll make a trip to my LSMG tomorrow and hope he's got some.

Does anyone have any idea of what the correct number for this needle might be?

Well, she's kinda ugly and I think I'll name her something appropriate as soon as I can think of something.

Joe