Originally Posted by

J Miller

Singer 500 is breaking it's top thread constantly.

OK, machine is a derelict that someone has messed with a bit and has some missing parts.

I have found enough parts to put it back in action:

Oiled and greased everything that moves.

Freed up the cam stack selectors.

Cleaned the hook area and the bobbin case.

Adjusted the bobbin case tension, there was none when I got it.

Adjusted the top tension, it was too tight.

Put in brand new unused needle.

The needle to hook timing is good.

The top and bobbin tension looks good when it sews.

After about an inch or two you'll hear a crunch, then a couple more stitches another crunch and the top thread breaks.

I'm not sure what's gonna become of this machine, but I want to see if I can make it sew before we make our decision.

Anybody have any ideas on what else to look for?

Joe

Alright the problem is solved and it was none of the above. But in trying to diagnose the problems I did the following:

Took apart the top tension assembly and cleaned it. Didn't have to, it wasn't the problem, but it never hurts.

Cleaned the bobbin case and hook assembly again.

I went hunting for a couple pics someone here on the forum emailed me of how to assemble the later top tensions. I didn't find it but I found out I had a 500 manual on my thumb drive. So I checked it out and found I had missed a complete step in threading the top end. I printed the page I needed then stood in front of our 401A while I double checked my assembly of the top tension.

Went back downstairs put the tension unit in and rethreaded it correctly.

Then I tried to sew and it made it a whole 3" then crunch and broke the thread. Over and over again my wife and I (she finally got in on the act) worked with the tensions, bobbin, and cleaning trying to find out what the heck it's problem was.

Then it went crunch and just stopped. Rather than go again and break the thread I carefully removed the needle and needle plate to see where the jam up was. Well, the thread was wrapped around the bobbin case and then around the case support on the back side where the case sits. This didn't make sense at all.

It was about then that I realized the bobbin case and hook assembly and the springy thing that holds the bobbin case in was the same as the 401A. So I went upstairs again and opened up the 401A and studied it. Hmmmmmmmm.

Back downstairs to the 500. Make one adjustment and zoom zooom we're sewing. No broken threads, ZZ works, stitch patterns work, and I'm thrilled. I had to go back upstairs to get a slant shank special purpose foot to really try some patterns and when I did, the old lady made a few really nice stitches.

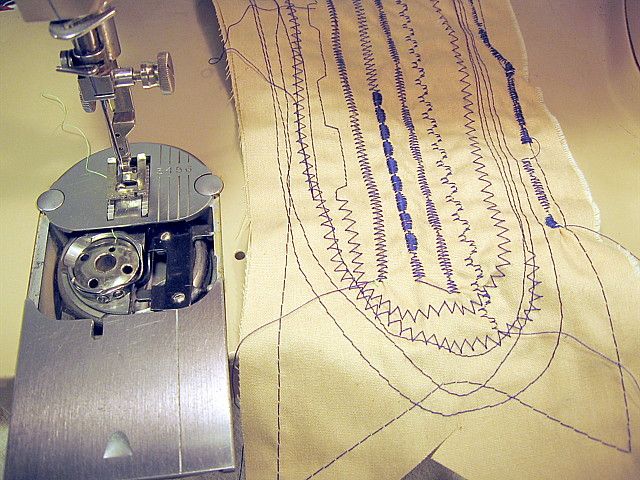

Now, I'm gonna post a pic of the bobbin area and let you all try and figure out what I had to adjust to fix the problem.

Joe