The tension bolt (a sort of split end screw) has to be straight. On some machines it has taken a hit, and needs to be bent back into place. The two threaded split ends sometimes need to be pushed in for the outer nut to go on the threads, but that's within normal. As long as the parts in the assembly move freely, and the disks give proper tension it should be fine. Make sure the parts from presser bar lever to the tiny metal part (release pin) on the back of the tension bolt (behind the face plate) is clean and moves freely. I had a stubborn case on a 99 where the parts has gummed up, covered in grimey old oil. It took me a while befor I realised the problem, and I though I had cleaned and oiled every where several times. Double check that the tension works when the presser bar lever is down, and release when it's in up position.

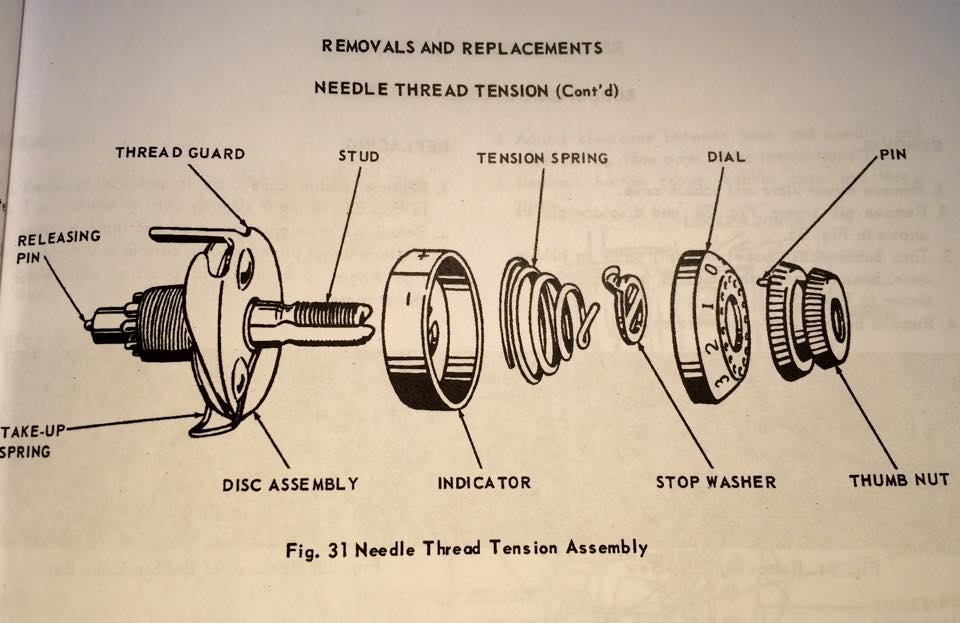

Double check that all parts are on the right way and in the correct order.