In my thread: Little Genie Magic Bobbin Washers, and what to do about a rattling bobbin case

{

http://www.quiltingboard.com/vintage...e-t203310.html }

I mentioned my HOTHER clone machine clattered like crazy when I sewed with it and the harder or faster I pushed it the more noise it made. It was actually ruining my concentration when sewing.

I posted the thread above and got a few suggestions. I decided to try some things I was thinking of as well as the shim and grease.

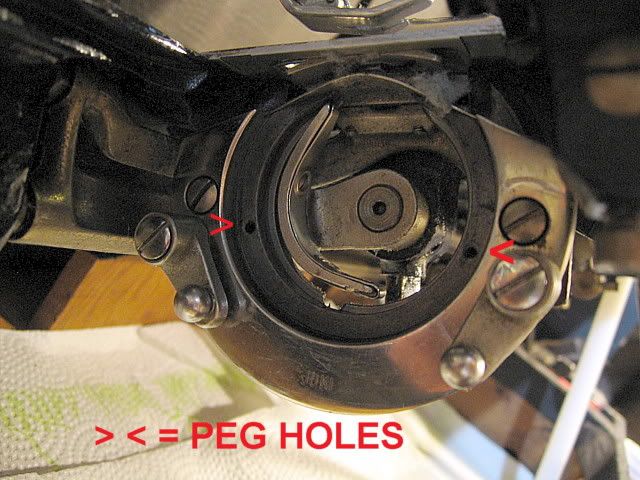

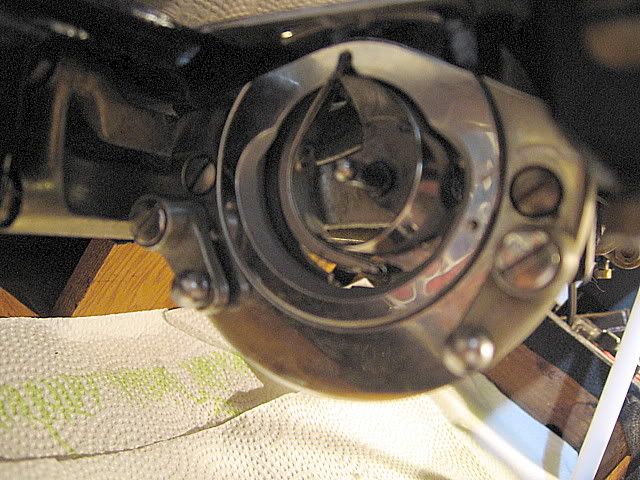

The first thing I found was the two locating pegs sticking out of the Hook Retainer were loose. This was allowing the Retainer to move back and forth as the Hook oscillated.

I took the pegs out and looked them over carefully. I was contemplating smacking them with a punch and hammer to deform them enough to fit tighter when I noticed someone else had already done so. I cleaned everything up and started putting the pegs back in and they didn't fit the same. They were tighter from one side than the other. So I put the pegs in so they fit tight, put the Hook Retainer back in making sure the pegs went into the holes in the housing:

Then tapped the Retainer home with a plastic hammer. This located the pegs for depth.

After that I removed the Retainer, and used some

Permatex Penetrating Grade Thread Locker Green for pre assembled parts on it to help keep them where they belong.

Then I reassembled the bobbin hook and parts and put the bobbin back in. Threaded it up and then tried it. Much, much, quieter. The Hook Retainer moving back and forth was the cause of most of the noise.

The next thing I did was hunt down a thin plastic food container lid and cut out a shim. I tried to make it the same size or a wee bit bigger than the bobbin, but it came out just a bit smaller. No problem though. I used an old paper hole punch to make the hole in the middle. It was the perfect size.

I put that in the machine and sewed some more. A bit less noisy but not significantly so.

Then I took the shim out and put some Tri-Flow grease on the peg like Candace mentioned.

And sewed some more. There didn't seem to be any noticeable noise reduction with the grease, and it made a mess in the bobbin hook. The insides of the hook were splattered with grease and the bobbin was covered with it. Not enough noise reduction to be worth the grease I wasted.

While I was sewing with the grease my bobbin ran out. So after cleaning the grease out of the hook I put in the shim and a full bobbin.

That is when I noticed the new full bobbin was slightly wider or thicker than the other bobbin. At first I even had a bit of trouble getting the case threaded. The thicker bobbin rim in addition to the shim was kind of in the way. But I got it threaded and in the machine and started sewing again.

After this experiment here are my thoughts:

>If the bobbin Hook assembly is in proper working order; in other words things that are not supposed to move don't, and things that are supposed to move do,

and you are using the proper bobbins you

shouldn't need the shims.

>I haven't measured them, but there seems to be a lot of variation in the height of bobbins. The thinner ones have more room to move about and might be one source of noise. My ears cannot hear high pitch sounds so unless the noises are really bad or within a sound range I can hear I won't notice them. As I continue to sew with the HOTHER I'll pay more attention to what bobbins I'm using, how they fit, and if there is any noise from them.

Not all 15 Clones are set up like the HOTHER, but if yours is and it's noisy, check the pegs in the Hook Retainer. They might be loose.

Joe