Singer 500 Rocketeer Rescue

#1

Super Member

Thread Starter

Join Date: Feb 2012

Posts: 8,091

Singer 500 Rescue

Last month I picked up three sewing machines and a box of cams and attachments from forum member Hedy. For the life of me I can’t remember her forum name. I posted about this somewhere, probably in the Vintage Sewing Machine Shop and can’t find it.

One of the machines was a Singer 500. She was in New Mexico and spotted a box of cams and posted about them in a thread about did anyone want cams or something like that. I piped up and said yes I’d take them. Get them if you can and I’ll buy them from you. So she did. Turns out that a Singer 500 sewing machine went with the cams. The machine was missing pieces and the top was off but what the heck I’d wanted to mess with one and here it was basically free.

After she returned to IL it took several weeks and a couple reschedulings for us to get together. We ended up having a good visit and buying two machines besides the 500.

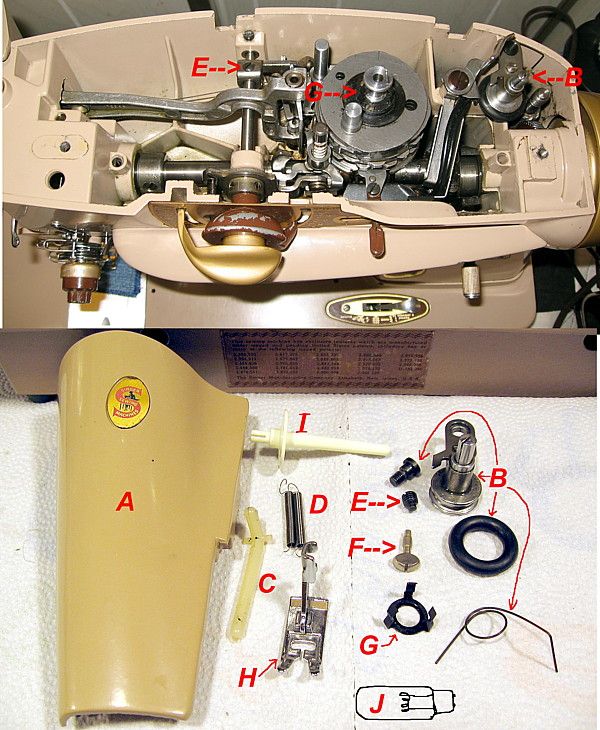

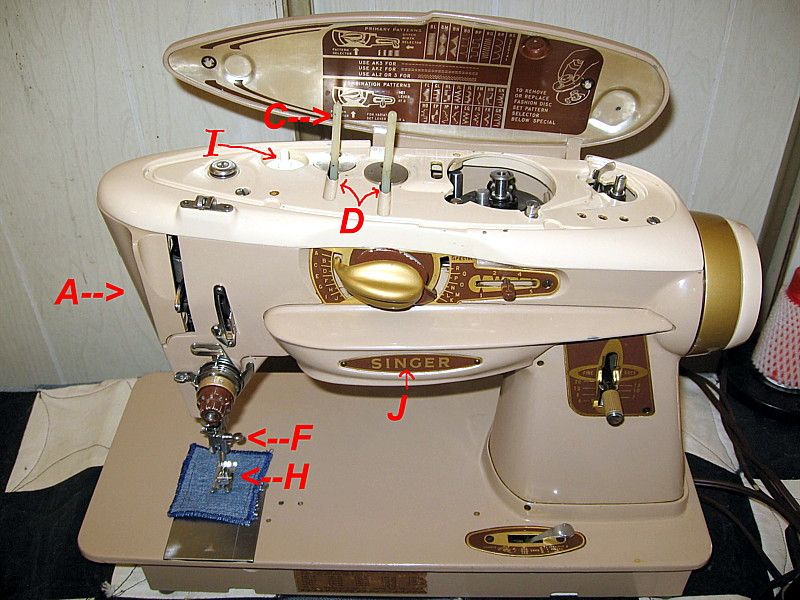

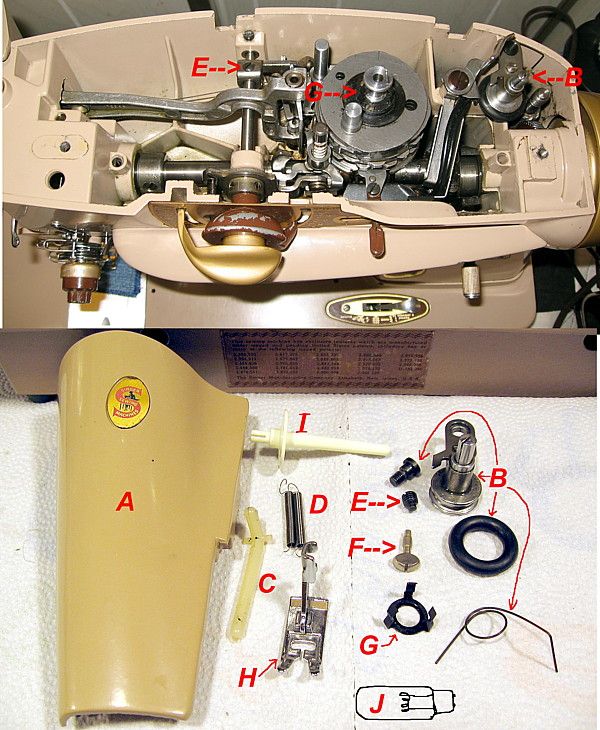

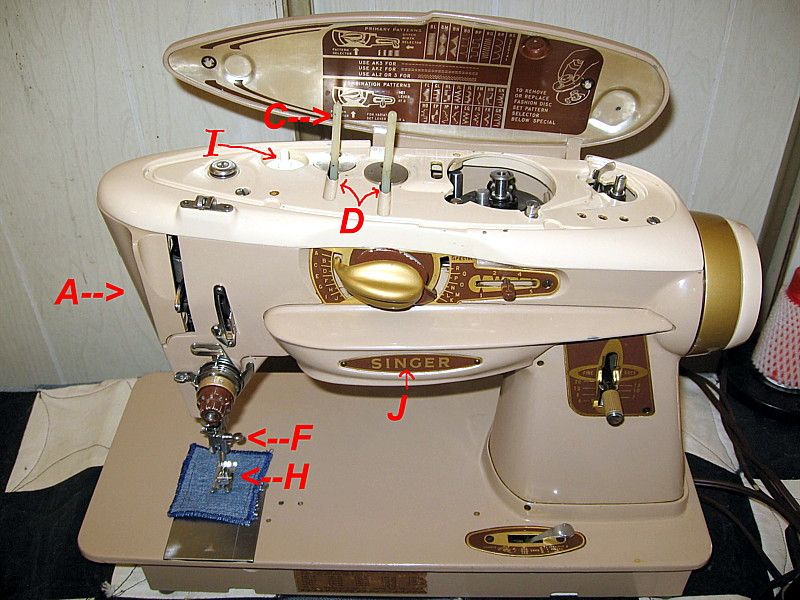

When we got home I looked the 500 over and wondered if it would ever run again. It was a mess inside. There was grease and old oil everywhere. One of the missing parts was the outer stitch selector knob set screw; “E” in the pic below.

The nob had been turned 180° from where it was supposed to be. You can see this in Hedy's picture above.

The bobbin winder assembly “B” was missing as was the spring clip “G” that holds the cam on top of the stack.

The face plate “A”, presser foot “H”, needle clamp screw “F”, light bulb “J”, one of the two spool pins “C” and both spool pin springs “D” were also missing.

I came up with a substitute set screw to lock down the stitch control knob and took the foot from my parts box and tried it out. Surprisingly it sewed. I was really amazed. It had some tension problems so I had to take the top tension apart to clean and adjust it, and also clean the bottom a couple times to get all the junk out.

Turns out the springy part that holds the bobbin case in was adjusted too far away and that was allowing the thread to wind around the case and jam up.

After getting that squared away, I set to and started cleaning. By the time I got it clean enough to satisfy me I’d used a half box of q-tips and quite a bit of denatured alcohol. But it was much better. I gave it good oiling and greasing with Tri-Flow, and then waited till Monday to get the parts.

I had the presser foot, the bulb and the extra spool pin “I” and had to get all the rest from my LSMG. For all those things he only charged me $25.00.

It didn’t take long at all to install the replacement parts, less than a half hour really. I oiled it some more and made sure that all the gears were greased. Then we started sewing for real.

Here are some more pics to make the text shorter.

Before:

Parts replaced:

After:

Testing the patterns and cams:

Whacky bag:

While sewing on the Whacky Bag I kept hearing the unmistakable sound of a bearing howling. So I might have to replace the motor shaft upper bearing. I’ll check with the LSMG first and if he’s got it I’ll get it from him. If not then Sew-Classic has them. And I might have to do a bit of fine tuning with the presser foot shaft and ZZ adjustments. But for the most part the old girl is up and running again. One more rescued machine.

Joe

Last month I picked up three sewing machines and a box of cams and attachments from forum member Hedy. For the life of me I can’t remember her forum name. I posted about this somewhere, probably in the Vintage Sewing Machine Shop and can’t find it.

One of the machines was a Singer 500. She was in New Mexico and spotted a box of cams and posted about them in a thread about did anyone want cams or something like that. I piped up and said yes I’d take them. Get them if you can and I’ll buy them from you. So she did. Turns out that a Singer 500 sewing machine went with the cams. The machine was missing pieces and the top was off but what the heck I’d wanted to mess with one and here it was basically free.

After she returned to IL it took several weeks and a couple reschedulings for us to get together. We ended up having a good visit and buying two machines besides the 500.

When we got home I looked the 500 over and wondered if it would ever run again. It was a mess inside. There was grease and old oil everywhere. One of the missing parts was the outer stitch selector knob set screw; “E” in the pic below.

The nob had been turned 180° from where it was supposed to be. You can see this in Hedy's picture above.

The bobbin winder assembly “B” was missing as was the spring clip “G” that holds the cam on top of the stack.

The face plate “A”, presser foot “H”, needle clamp screw “F”, light bulb “J”, one of the two spool pins “C” and both spool pin springs “D” were also missing.

I came up with a substitute set screw to lock down the stitch control knob and took the foot from my parts box and tried it out. Surprisingly it sewed. I was really amazed. It had some tension problems so I had to take the top tension apart to clean and adjust it, and also clean the bottom a couple times to get all the junk out.

Turns out the springy part that holds the bobbin case in was adjusted too far away and that was allowing the thread to wind around the case and jam up.

After getting that squared away, I set to and started cleaning. By the time I got it clean enough to satisfy me I’d used a half box of q-tips and quite a bit of denatured alcohol. But it was much better. I gave it good oiling and greasing with Tri-Flow, and then waited till Monday to get the parts.

I had the presser foot, the bulb and the extra spool pin “I” and had to get all the rest from my LSMG. For all those things he only charged me $25.00.

It didn’t take long at all to install the replacement parts, less than a half hour really. I oiled it some more and made sure that all the gears were greased. Then we started sewing for real.

Here are some more pics to make the text shorter.

Before:

Parts replaced:

After:

Testing the patterns and cams:

Whacky bag:

While sewing on the Whacky Bag I kept hearing the unmistakable sound of a bearing howling. So I might have to replace the motor shaft upper bearing. I’ll check with the LSMG first and if he’s got it I’ll get it from him. If not then Sew-Classic has them. And I might have to do a bit of fine tuning with the presser foot shaft and ZZ adjustments. But for the most part the old girl is up and running again. One more rescued machine.

Joe

#4

Super Member

Join Date: Dec 2011

Location: Northern CA near Sacramento

Posts: 1,107

Joe,

A screaming bearing on those motor many times only means the bearing is dried out. Try dripping a few drops of a heavy motor oil into the well that is at the base of the gear on top of the motor. With luck this heavy oil will soften the dried lube in the bearing after running it for a few minutes. I have used this method several times and have never had to replace the bearing.

Cathy

A screaming bearing on those motor many times only means the bearing is dried out. Try dripping a few drops of a heavy motor oil into the well that is at the base of the gear on top of the motor. With luck this heavy oil will soften the dried lube in the bearing after running it for a few minutes. I have used this method several times and have never had to replace the bearing.

Cathy

Singer 500 Rescue

While sewing on the Whacky Bag I kept hearing the unmistakable sound of a bearing howling. So I might have to replace the motor shaft upper bearing. I’ll check with the LSMG first and if he’s got it I’ll get it from him. If not then Sew-Classic has them. And I might have to do a bit of fine tuning with the presser foot shaft and ZZ adjustments. But for the most part the old girl is up and running again. One more rescued machine.

Joe

While sewing on the Whacky Bag I kept hearing the unmistakable sound of a bearing howling. So I might have to replace the motor shaft upper bearing. I’ll check with the LSMG first and if he’s got it I’ll get it from him. If not then Sew-Classic has them. And I might have to do a bit of fine tuning with the presser foot shaft and ZZ adjustments. But for the most part the old girl is up and running again. One more rescued machine.

Joe

#5

Super Member

Thread Starter

Join Date: Feb 2012

Posts: 8,091

Joe,

A screaming bearing on those motor many times only means the bearing is dried out. Try dripping a few drops of a heavy motor oil into the well that is at the base of the gear on top of the motor. With luck this heavy oil will soften the dried lube in the bearing after running it for a few minutes. I have used this method several times and have never had to replace the bearing.

Cathy

A screaming bearing on those motor many times only means the bearing is dried out. Try dripping a few drops of a heavy motor oil into the well that is at the base of the gear on top of the motor. With luck this heavy oil will soften the dried lube in the bearing after running it for a few minutes. I have used this method several times and have never had to replace the bearing.

Cathy

Thanks for the tip. I did put a few drops of Tri-Flow down there and that seems to have helped. A couple more drops of motor oil might do the trick.

Joe

#7

Super Member

Thread Starter

Join Date: Feb 2012

Posts: 8,091

If I have to pull the motor to put in a bearing I'll be sure to check the brushes and springs and clean it real good while I'm at it.

I've seen brushes for the potted motor machines and the FWs, but I've not seen any for the internal motors such as this 500 uses.

Where would I look for them?

Joe

I've seen brushes for the potted motor machines and the FWs, but I've not seen any for the internal motors such as this 500 uses.

Where would I look for them?

Joe

#8

http://www.quiltingboard.com/vintage...ml#post5662188

ETA: Assuming the 500 uses the same motor as the 400,... can you confirm?

#10

I was only referring to the brushes.  I haven't had a motor bushing in my hands yet.

I haven't had a motor bushing in my hands yet.

Which brushes worked on the 401? When I googled the part number ( in the other thread) the brushes were the FW / 201-2 brushes,... Are those the ones you used? Is the motor the same in the 500? I don't think I have a chart for it, and I'm stiff today so I don't know when I'll get into the sewing room to flip some machines around.

I haven't had a motor bushing in my hands yet.

I haven't had a motor bushing in my hands yet. Which brushes worked on the 401? When I googled the part number ( in the other thread) the brushes were the FW / 201-2 brushes,... Are those the ones you used? Is the motor the same in the 500? I don't think I have a chart for it, and I'm stiff today so I don't know when I'll get into the sewing room to flip some machines around.

Thread

Thread Starter

Forum

Replies

Last Post

ladydukes

For Vintage & Antique Machine Enthusiasts

2

11-10-2014 08:34 AM