When is a machine "just not worth it"?

#21

Super Member

Join Date: Jan 2010

Location: Outer Space

Posts: 9,319

Please, please, be careful breathing fumes from any solvents. Several of my friends who have had exposure to solvents have developed bladder cancer, pancreatic cancer and liver cancer. Physicians said it was from exposure to those solvents. A printer from Illinois had cancer from cleaning his printing presses. Don't know how much it takes, but please take precautions, gloves and respirators. Live is too short anyway.

#22

Member

Join Date: Aug 2012

Location: Glendon, Moore County, NC

Posts: 36

I'm pretty sure this 127 would classify as an extreme case. YUCK. I'm about 80± % finished cleaning it. I'm going to borrow the top tension spring off of my 66-1 and test sew with it today. Depending on how that works will decide it's fate.

The idea of running it through a car wash using the high pressure wand intrigues me. ( Do we have a devil icon here?)

Joe

The idea of running it through a car wash using the high pressure wand intrigues me. ( Do we have a devil icon here?)

Joe

I am not as experienced as so many of the seamstress here on this website; irregardless, that is not saying I would not love to be as talented as they are. However, after listening to you on numerous occassions now, I can't help but wonder, if I am cleaning my machine enough.

I found the machine I am most fond of a older Turquoise blue "White" in a cabinet in a Christian Thrift Store for $20.00. It only had one cam. I brought it home, cleaned the bobbin area taking the bobbin out as far as I could, rubbing with an old bath cloth all the parts underneath, then oiled it down very well, with towel on the floor, with store bought sewing machine oil. Truly I felt it was in pretty good shape. However, I let it sit for a couple of days, then tried her out. She sewed beautiful. I guess I have had her right at a year now, and must say that is the best $20.00 I have ever spent.

I don't want the oil to gunk up this machine. I have a great workhorse machine, and want to keep it that way. What should I be doing to keep the oil from accumulating as you speak of often here on this website?

Thank you for your help with this!

Barbara

#23

Power Poster

Join Date: Mar 2011

Location: Somewhere

Posts: 15,507

The only oil you need to really worry about is the bit dried up inside the moving parts - in other words - worry about the dried up gunk you CAN'T see. Tri-flow is supposed to be safe - I try to keep it off my hands though. The regular machine oil has paraffin in it and it does set up. 3-in-1 oil sets up like concrete. When you do use the chemicals mask up etc then drink a LOT of water and flush your system. I would much rather see too much oil than rust of any kind. I would suppose you could get too much solvent in those moving areas and encapsulate solvent. I would only do that much cleaning on a really bad machine - most machines will just take a gentle cleaning. We are not talking about the average machine - we are talking about some really nasty messes. I give up on a machine that is rusted out. I know Joe and others here fix them up anyway. I have to be pretty careful with the chemicals with the chemical exposure I've already had. To keep from building up oil, just clean often and wipe up excess as you go.

#24

Super Member

Thread Starter

Join Date: Feb 2012

Posts: 8,091

The machine I was talking about was so bad internally and underneath that all the parts were black with the built up solidified oil.

Caked with it to the point you could not see the joints or seams or screw heads of the parts. How the machine worked is beyond me.

I've had others similar to this, the Minnesota A and B, but no where near as hard to clean.

The few pics I have of this machine do not show just how horribly grungy the outside of this machine was.

I would equate sewing with it to cooking new food on a filthy frying pan.

When I say to clean a machine I'm not saying to strip it down every time, just wipe the excess oil of the bottom and keep the outside and small parts clean.

Joe

Caked with it to the point you could not see the joints or seams or screw heads of the parts. How the machine worked is beyond me.

I've had others similar to this, the Minnesota A and B, but no where near as hard to clean.

The few pics I have of this machine do not show just how horribly grungy the outside of this machine was.

I would equate sewing with it to cooking new food on a filthy frying pan.

When I say to clean a machine I'm not saying to strip it down every time, just wipe the excess oil of the bottom and keep the outside and small parts clean.

Joe

#26

Super Member

Thread Starter

Join Date: Feb 2012

Posts: 8,091

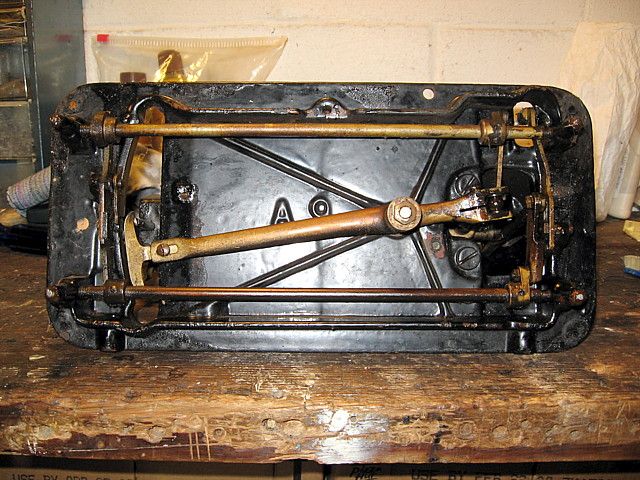

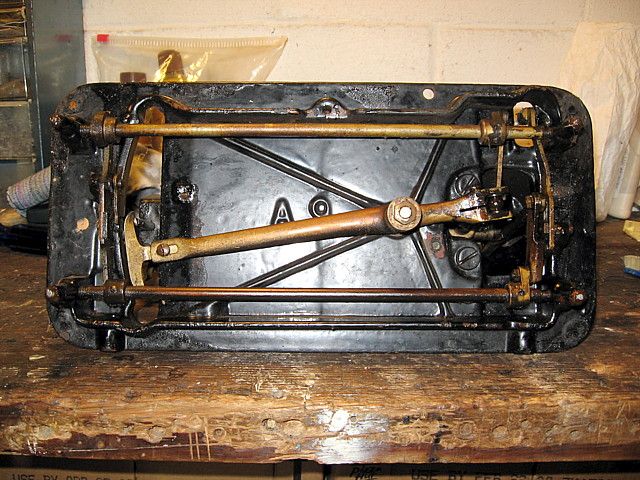

Here is an example.

This is the underside of the Minnesota A I have. If you'll notice just how built up and caked on the old oil is, well the 127 that started this thread was worse. At least with the Minnesota you could see the steel colored parts through the old oil, but with the 127 those parts were black with oil and you couldn't tell them from the black painted underside of the bed.

These machines were used and used and used and probably oiled with an organic oil such as whale oil or something like that that doesn't respond well to kerosene and never wiped down or cleaned. That's about the only theory I have right now.

Joe

This is the underside of the Minnesota A I have. If you'll notice just how built up and caked on the old oil is, well the 127 that started this thread was worse. At least with the Minnesota you could see the steel colored parts through the old oil, but with the 127 those parts were black with oil and you couldn't tell them from the black painted underside of the bed.

These machines were used and used and used and probably oiled with an organic oil such as whale oil or something like that that doesn't respond well to kerosene and never wiped down or cleaned. That's about the only theory I have right now.

Joe

#28

Super Member

Thread Starter

Join Date: Feb 2012

Posts: 8,091

I wish I could Miriam, but I just can't stand that horrid build up especially when it hides the flaws and needs of the machine.

Like the little screw on the clamp in of one of the crosswise rods. Got to find one.

Joe

Like the little screw on the clamp in of one of the crosswise rods. Got to find one.

Joe

Thread

Thread Starter

Forum

Replies

Last Post

bearisgray

General Chit-Chat (non-quilting talk)

65

02-01-2024 09:04 AM

grant15clone

For Vintage & Antique Machine Enthusiasts

28

07-28-2019 03:27 AM