"New to me" Singer 319W.

#61

Junior Member

Thread Starter

Join Date: Jan 2014

Posts: 160

I will try to put a pic up later.

Nope, they haven't arrived yet. The ones coming aren't Ti, just chrome. In theory, there should be no difference. The Ti is just a coating like the chrome ones...

Last edited by great white; 02-06-2014 at 12:33 AM.

#63

Junior Member

Thread Starter

Join Date: Jan 2014

Posts: 160

But I was doing the test stitches on 4 layers of denim and a schmetz (size 18) 15x1 at the end.

No damage, no stitch quality issues of any sort. Thats pretty thick and no aparant needle deflection, no damage at least.

Could be that mine is just a "factory freak" of some sort.

If true, that will make the hlx5 needle test on line of little use to other 319w machines.

About all I will be able to do is compare measured lengths with the 206x13 needles and someone else will have to see if it works.

Last edited by great white; 02-06-2014 at 03:57 PM.

#65

Super Member

Join Date: Feb 2012

Posts: 8,091

Thanks for the pics. Those bobbin cases look like the ones for the Singer 206. Some say they interchange with the 319s, some say they don't, and some say it depends on the hook number. I say ..... I don't have the slightest idea.

Joe

Joe

#66

).

).It still seems that the slightly shorter hlx5 needles would give you a better chance of avoiding a bobbin case catastrophe.

#67

Junior Member

Thread Starter

Join Date: Jan 2014

Posts: 160

While I don't have a 206/306, what I have read on it indicated that the bobbin case is indeed different and it depends on the hook.

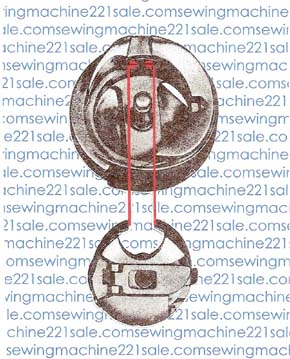

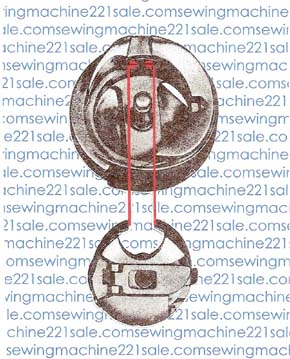

It appears the 206/306 uses and "open slot" case in order to align with two pins at the top which prevent it from spinning:

Singer rotary style open front bobbin case for bobbin case holder and sewing hook #173061 (as viewed from the front). For models: 206, 206K, 206W, 306, 306W,(NNN) NNN-NNNNbr />SPECIAL NOTE: Do not choose the bobbin case according to your model number . You MUST choose from the type of sewing hook. Please note the two guide posts (red) at the top of the bobbin case holder. You will need to examine your machines sewing hook / holder in order to choose the correct bobbin case. This bobbin case #XXXXX will NOT work with sewing hook #173061.

Uses bobbins #55623NS

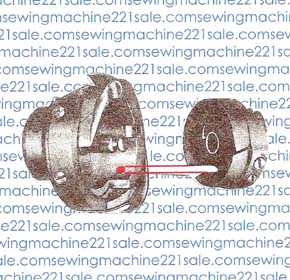

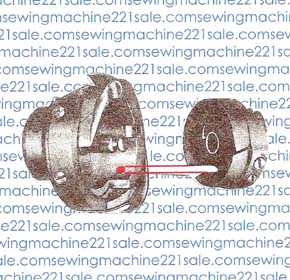

The later versions (like my 319W) use a single pin at around the 4 o'clock position:

Singer rotary style closed front bobbin case for bobbin case holder and sewing hook #173061 (as viewed from the side).

For models: 206, 206K, 206W, 306, 306W,(NNN) NNN-NNNNbr />SPECIAL NOTE: Do not choose the bobbin case according to your model number . You MUST choose from the type of sewing hook. Please note the guidepost (red) at the lower right hand side of the bobbin case holder. You will need to examine your machines sewing hook / holder in order to choose the correct bobbin case.

This bobbin case #XXXXX will NOT work with sewing hook #276254.

This seems to be why the difference in cases. Not so the needle doesn't hit it, but the difference in positioning and securing the bobbin case.

To further complicate the issue, I've read several posts about a German built 306 that uses 15x1 needles instead of the 206x13 and actually says so in the owners manual. It was a singer 306M if I recall....

It appears the 206/306 uses and "open slot" case in order to align with two pins at the top which prevent it from spinning:

Singer rotary style open front bobbin case for bobbin case holder and sewing hook #173061 (as viewed from the front). For models: 206, 206K, 206W, 306, 306W,(NNN) NNN-NNNNbr />SPECIAL NOTE: Do not choose the bobbin case according to your model number . You MUST choose from the type of sewing hook. Please note the two guide posts (red) at the top of the bobbin case holder. You will need to examine your machines sewing hook / holder in order to choose the correct bobbin case. This bobbin case #XXXXX will NOT work with sewing hook #173061.

Uses bobbins #55623NS

Singer rotary style closed front bobbin case for bobbin case holder and sewing hook #173061 (as viewed from the side).

For models: 206, 206K, 206W, 306, 306W,(NNN) NNN-NNNNbr />SPECIAL NOTE: Do not choose the bobbin case according to your model number . You MUST choose from the type of sewing hook. Please note the guidepost (red) at the lower right hand side of the bobbin case holder. You will need to examine your machines sewing hook / holder in order to choose the correct bobbin case.

This bobbin case #XXXXX will NOT work with sewing hook #276254.

To further complicate the issue, I've read several posts about a German built 306 that uses 15x1 needles instead of the 206x13 and actually says so in the owners manual. It was a singer 306M if I recall....

Last edited by great white; 02-07-2014 at 01:44 PM.

#69

Junior Member

Thread Starter

Join Date: Jan 2014

Posts: 160

Was repairing the veneer today in prep for refinishing and took a little polish to the dirty drawer handles.

50's quality strikes again. Solid brass.

A little jewelers rouge with the polish wheel and they will clean up nicely.

They will look great on the refinished table.

50's quality strikes again. Solid brass.

A little jewelers rouge with the polish wheel and they will clean up nicely.

They will look great on the refinished table.

Last edited by great white; 02-08-2014 at 05:47 PM.

Thread

Thread Starter

Forum

Replies

Last Post

bearisgray

General Chit-Chat (non-quilting talk)

65

02-01-2024 09:04 AM

harrishs

For Vintage & Antique Machine Enthusiasts

19

07-30-2012 12:27 AM