Vintage Sewing Machine Shop.....Come on in and sit a spell

Power Poster

Join Date: Mar 2011

Location: Somewhere

Posts: 15,507

HELP!! Am working on a 99 right now and need some advice. Trying to get tophat pice off. We've undone the set screw on its side but are wondering if we need to somehow undo the inner dohickey that looks, to my hubby, like another screw possibly holding it on. Any and all help greatly appreciated.

Chris

Chris

Power Poster

Join Date: Mar 2011

Location: Somewhere

Posts: 15,507

Sorry about interrupting the Mowgli discussion, but this is an official request for help

Meet my EDISON,

He has several problems. First was the feed dogs hit the front side of the needle plate. I adjusted that so it doesn't happen, but either I caused another problem, or it was there but I didn't know it. I suspect it was there as when he was put in reverse he banged and clunked horribly. Now he only does that if I hold the stitch lever down.

When the stitch lever is lowered all the way to the bottom for maximum length stitches, the feed regulator (T2, Figs 30 and 32 ) in the 15-91 service manual is in the way of the cam next to it.

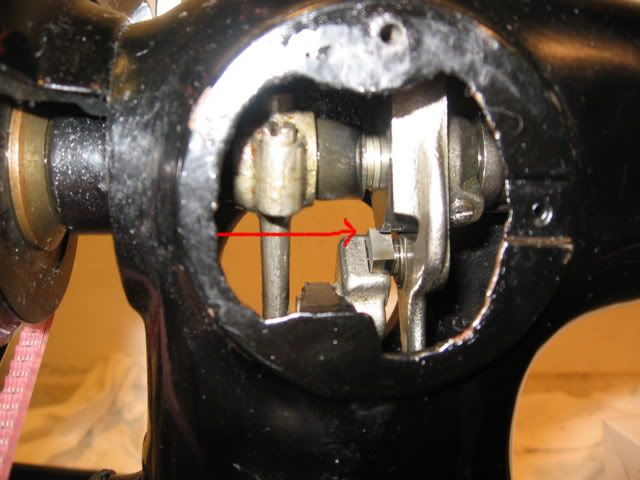

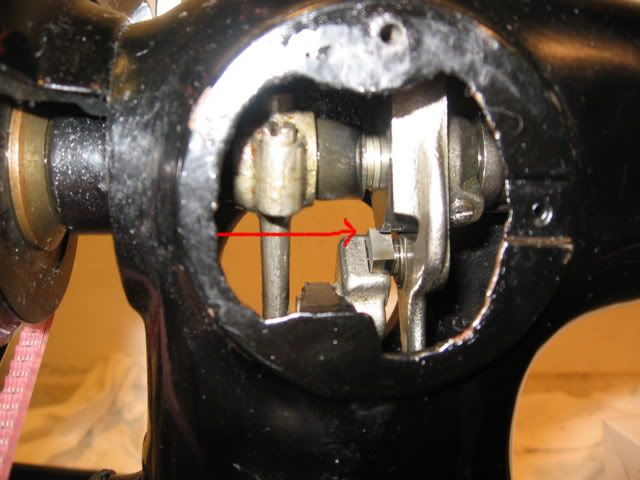

The arrow points to the interference point in the following pictures:

The cam smacks the sliding part of the regulator moving it out of the way.

In the first pic you can just barely see that the forward edge of the sliding part T2 has been beveled. I don't know if this is OEM or was done after the machine left the factory. If you look at the screws it's easy to see that some ham fisted bubba has been inside this thing.

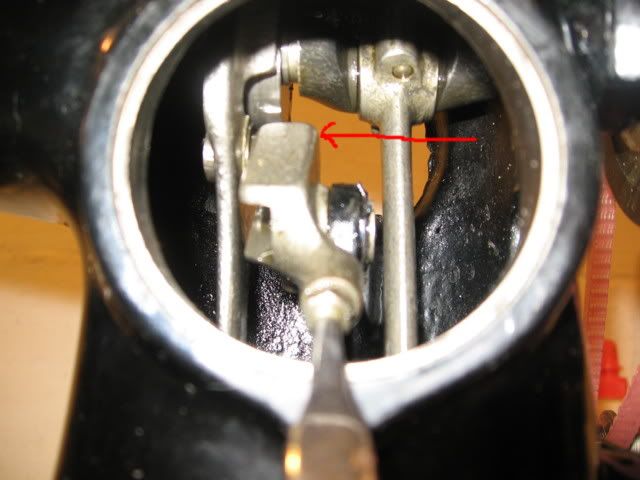

Here's a front view:

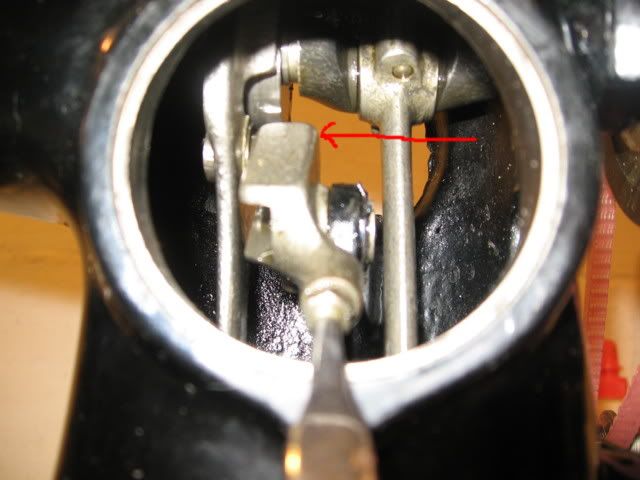

And a bottom view:

This particular machine is closer to the Singer 15-91 than my other one so I suppose the instructions in the manual will work. But, I am not experienced enough to really understand all the ins and outs of what I'm reading.

So ~ I need some help. Just specifically what do I adjust to cure the interference problem and make sure the feed dogs are right too.

Joe

Meet my EDISON,

He has several problems. First was the feed dogs hit the front side of the needle plate. I adjusted that so it doesn't happen, but either I caused another problem, or it was there but I didn't know it. I suspect it was there as when he was put in reverse he banged and clunked horribly. Now he only does that if I hold the stitch lever down.

When the stitch lever is lowered all the way to the bottom for maximum length stitches, the feed regulator (T2, Figs 30 and 32 ) in the 15-91 service manual is in the way of the cam next to it.

The arrow points to the interference point in the following pictures:

The cam smacks the sliding part of the regulator moving it out of the way.

In the first pic you can just barely see that the forward edge of the sliding part T2 has been beveled. I don't know if this is OEM or was done after the machine left the factory. If you look at the screws it's easy to see that some ham fisted bubba has been inside this thing.

Here's a front view:

And a bottom view:

This particular machine is closer to the Singer 15-91 than my other one so I suppose the instructions in the manual will work. But, I am not experienced enough to really understand all the ins and outs of what I'm reading.

So ~ I need some help. Just specifically what do I adjust to cure the interference problem and make sure the feed dogs are right too.

Joe

makes you wonder if someone dropped the machine on the balance wheel or something. Maybe read the bit 'never force it get a bigger hammer' during a repair. I believe I have one with a problem in that same area - I've kind of been going back and forth trying to decide if it is a parts machine or something that can be revived - meanwhile it is on the shelf waiting for it's moment I guess.... sure does turn nice.

Sorry I'm no help.

Super Member

Join Date: Feb 2012

Posts: 8,091

Super Member

Join Date: Feb 2012

Posts: 8,091

makes you wonder if someone dropped the machine on the balance wheel or something. Maybe read the bit 'never force it get a bigger hammer' during a repair. I believe I have one with a problem in that same area - I've kind of been going back and forth trying to decide if it is a parts machine or something that can be revived - meanwhile it is on the shelf waiting for it's moment I guess.... sure does turn nice.

All the internal screws that you'd turn to adjust things are really buggered up.

I'm hoping to find a cure without resulting to brute force or euthanasia (parting out). I will continue to study the poor pictures in the manual, perhaps it will begin to make sense. I can only hope.

Joe

Power Poster

Join Date: Mar 2011

Location: Somewhere

Posts: 15,507

Joe, you have permission to have a parts machine. Too bad it is such a pretty machine. It feels better when the parts machine is butt ugly. Maybe you can find an ugly one and combine them.

My parts machine is butt ugly because of all the rust. It is a 99 with a motorectomy and several other missing parts but am hopeful it can help save others' lives like organ donors.

Super Member

Join Date: Feb 2012

Posts: 8,091

Well, I've told these stories before, but let me tell you again. I was given a 99K that was rusted tight. I stripped it of all it's useable parts as I oiled it and cleaned it and finally broke it loose. Now I've got 99% of the parts cleaned and oiled and I'm down to giving it a kerosene flush bath and replacing three parts. I've removed all the parts I donated to other machines and returned them to Rusty, replacing them with new. When I'm finished it will be a functional machine again. I bought a 66-18 from Goodwill auction. It arrived with a busted motor, their fault, and a broken needle take-up lever. I didn't see this in the auction pics. I took it to my LSMG who sold me a 66-4 for parts. Well, I acquired the parts to fix both the 66-18 and the 66-4. I bought a 66-4 Treadle that had been electrified decades ago. The motor was gone, but the light, wiring block, and foot controller were there. The wiring was so brittle it was falling apart like raw spaghetti. I worked on replacing the missing parts to the treadle and even rewired the cord block, light and foot controller. During the acquisition of the replacement parts I found another treadle on CL that had a broken stand. Turns out the machine is a 9W-7. I cleaned the machine and tested it, works beautiful. And when the weather turns I'll get to the cabinet. So you see, I just can't part one out if it's at all fixable. I'm the same way with guns and cars and antique fans. I'm pushing 60. If I've learned anything in my life, it's patience. I'll get it figured out. If not now, then later. Joe

Last edited by J Miller; 03-07-2012 at 06:05 PM. Reason: spelling and text formation

Power Poster

Join Date: Mar 2011

Location: Somewhere

Posts: 15,507

Yup organ donors save lives. It's not like you are actually destroying a machine - you might help maybe 10 others to stay alive - maybe more. I figure somebody took apart a perfectly good machine to sell parts on Ebay.... so why not part out a perfectly terrible machine. I have learned a lot dis-assembling dead machines though. Nothing to lose Joe and you might get it back together some day Joe.

Super Member

Join Date: Feb 2012

Posts: 8,091

Miriam,

I'll stick it out a while. I'm in no hurry.

Chris,

Your donor 99K have an oscillating hook, a needle take-up lever assembly, a feed dog and screw you'd sell me???

Joe

I'll stick it out a while. I'm in no hurry.

Chris,

Your donor 99K have an oscillating hook, a needle take-up lever assembly, a feed dog and screw you'd sell me???

Joe

Thread

Thread Starter

Forum

Replies

Last Post

Stitchnripper

Main

5

10-17-2018 09:01 AM

AngieS

Main

38

10-06-2011 10:06 PM

craftybear

Offline Events, Announcements, Discussions

34

09-09-2011 12:36 PM